Max Pegs™

R55.00 – R90.00 inc. VAT

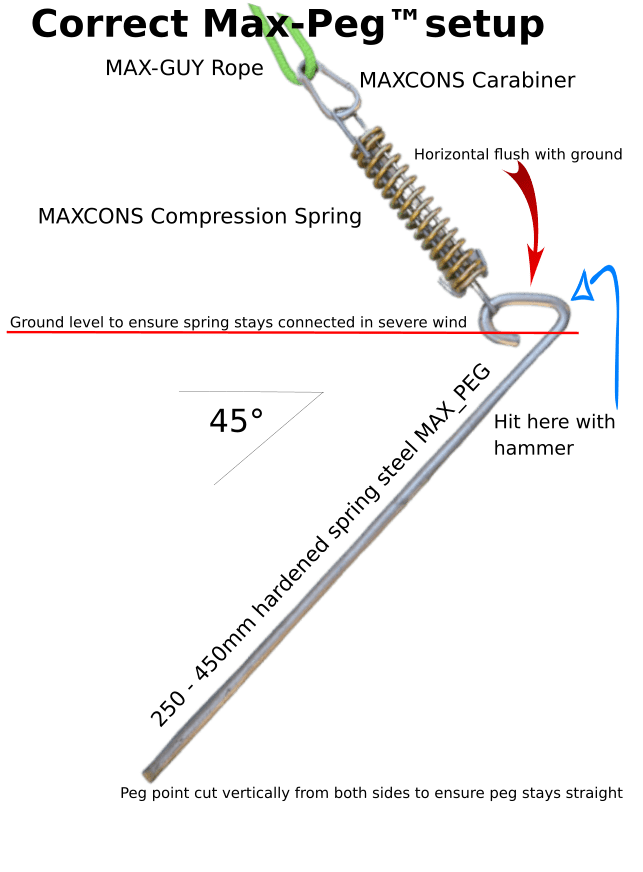

Max Pegs™ replace traditional L shaped tent pegs. Instead of one peg, there are two components: a 8mm thick hardened spring steel peg and a compression spring.

Description

Max Pegs™ replace traditional L shaped tent pegs. Instead of one peg, there are two components: a 8mm thick hardened spring steel peg and a compression spring.

Available in different sizes:

- 250mm Peg with a 25kg Spring (Ideal for Nylon Tents)

- 350mm Peg with a 45kg Spring (Ideal for Hard Ground)

- 450mm Peg with a 45kg Spring (Ideal for Soft or Sandy Soil)

- Also see 450mm Max Storm Pegs with 85kg Spring (Ideal for stormy weather)

Max Pegs™ are quality guaranteed, if one of our components break with normal use we will replace it.

Disadvantages of traditional ‘L’ tent pegs

-

In hammering the pegs, you are basically hitting the spring section of the peg. The hammer hops on the peg, so not every strike counts.

-

The hand holding the peg at the end of the “L” portion gets hurt by the vibration created by the hammer blows.

-

When the ground is solid the pegs are likely to bend as they are only 5mm spring steel.

-

The vertical spring action of these pegs which is supposed to hold your ropes tight is very limited.

-

The mechanical reaction to the spring action of the “L” peg causes the anchor portion to work itself out of the ground after a day or two in windy conditions. Hence, you only have temporary anchors, and you have to periodically inspect them to ensure they are still embedded.

-

“L” Pegs are temporary spot anchors and offer no counteraction from the other “L” Pegs around your tent. This causes the guide ropes to unhook, causing a total collapse of the structure.

-

When a slack guy rope suddenly receives a tug of wind, a snap action is created that causes the tent to tear.

How Max Pegs™ solve the problem

-

The anchor pegs are made from 8mm hardened steel and are 250mm, 350mm and 450mm in length; ideally suited to solid and soft ground conditions.

-

The peg head is designed so that you strike it virtually right on the shaft, without “hammer bounce” and each strike counts towards getting your peg into the ground.

-

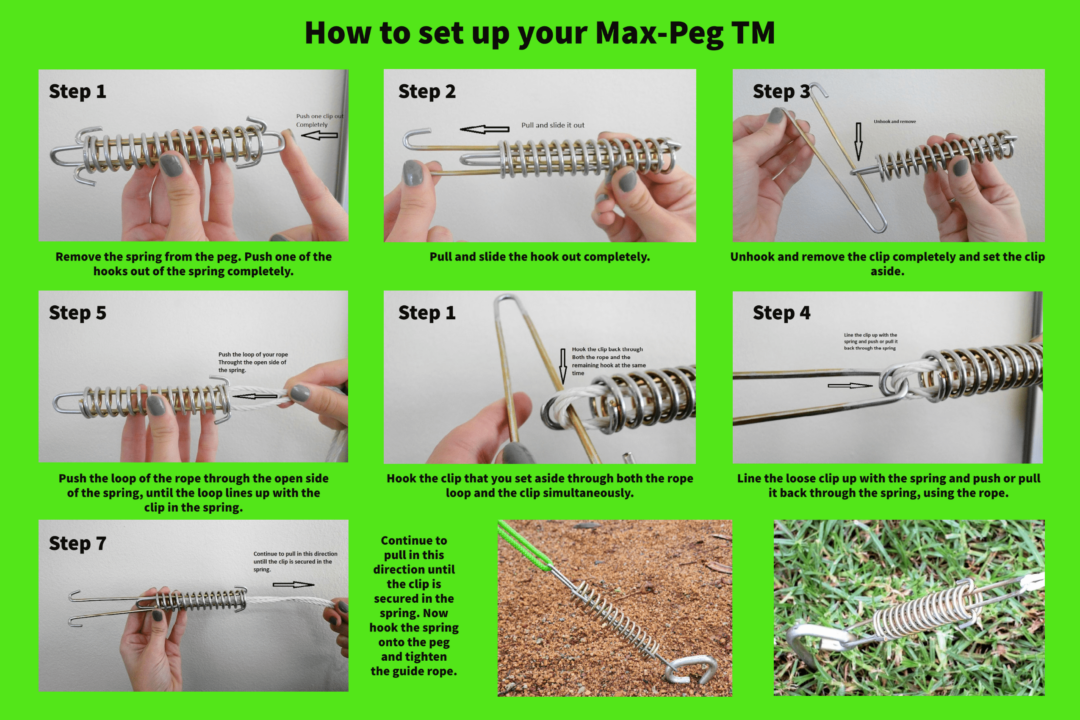

The head hook is designed to be a system of closed loops. When the spring is hooked on, the rope and spring cannot unhook themselves in windy conditions.

-

With this peg and spring, we have addressed all anchor issues. The spring action cannot work the anchor out of the ground. You now have a solid fixture that works and is easy to assemble.

-

When the springs get pulled up with your guide ropes, the tension on your seams and poles is proportionally spread as all the springs have the same strength.

-

You can only pull a spring half of its length with your hand strength which leaves enough spring action should the wind come up. Compression springs’ push and pull strength increase as it is pressured.

-

Since each spring works against another to get back to its original form, it holds your tent firmly in place.

-

A strong wind comes from one side of the tent. The springs on the “wind side” will contract, and the springs on the opposing side will release immediately and hold the tent firmly in place. If the wind suddenly changes direction, the springs react immediately and their whole action changes to the side the wind is coming from.

-

The ropes cannot be detached and the springs cannot unhook from the pegs. This is basically an “inverted suspension” system for your tent.

-

The spring action on every peg prevents any “snap” action experienced with normal tent pegs that would tear the tent and bend the tent poles.

-

Tension springs usually lose memory and need regular replacement. We use high-quality compression springs. This spring does not lose memory.

Additional information

| Length and Resistance | 250mm Peg – 25kg Spring (Nylon Tents), 350mm Peg – 45kg Spring (Solid Ground), 450mm Peg – 45kg Spring (Soft or Sandy Soil), 450mm Peg – 85kg Spring (Storm Peg) |

|---|

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.